Twin Head Blown Film Machine for Plastic Bag Manufacturers | POLYSTAR

Introducing POLYSTAR Twin Head Blown Film Machine with the motto of the company: "Extrusion Made Simple". The blown film extruder is specially designed for HDPE and LDPE bag producers. 【HIGHLIGTS OF Twin Head Blown Film Machine】 - Monolayer (1 Layer) - Two Die Heads, Single Screw - Film Width from 150~650mm - Extruder Dia: 45mm, 55mm, 75mm - Material: HDPE, LDPE - Output: 30~140 kg/hr - Works with virgin, recycled materials, Biomaterials, and CaCO3 - Possible end products: T-shirt bags, Bottom sealed flat bags, Shopping bags, Supermarket bags, Garbage bags 【MACHINE PORTFOLIO OF POLYSTAR】 1. BLOWN FILM MACHINES - One Layer Twin Head HDPE LDPE 650mm Machine - Multilayer Blown Film Machines - One Layer HDPE / LDPE 800mm (Mini type) Machine - AB - 2 Layer Co-Extrusion LDPE/LLDPE Machine - One Layer HDPE LDPE LLDPE 1500mm Machine 2. BAG MAKING MACHINES - Bottom Sealing Bag Making Machines - Folded Garbage Bags Machines - Perforated Bag on Roll Machines - Thick Bag Making Machines - Laundry Bags Machines 3. RECYCLING MACHINES - Plastic Recycling Machines - Plastic film recycling Machines - Two stage recycling Machines - Air cooled recycling Machines - Hopper feeding recycling Machines - Shredder integrated recycling Machines 【ABOUT POLYSTAR】 POLYSTAR is a pioneer manufacturer of Plastic Recycling Machines, Blown Film Extruders, and Plastic Bag Making Machines. The company has gained the trust of its customers with 32 years of experience in the industry, today POLYSTAR has been sold over 4,000 machines in 105 countries worldwide.

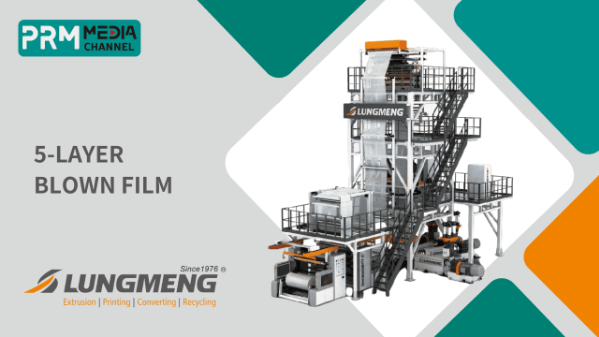

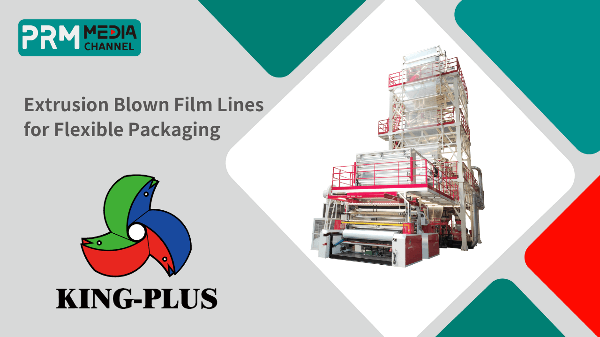

Extrusion Blown Film Lines for Flexible Packaging | KING PLUS

Three-layer blown film machine for lamination film Including: Auto air ring Gravimetric dosing system Internal bubble cooling system (IBC) In-line thickneess gauge Oscillating haul-off Back to back double winders Customized blown film machine to meet your need! Welcome to contact us!

Blown Film Machine HDPE LDPE LLDPE (ABA) Two Layer | KANG CHYAU

Introducing Blown Film Machine from one of the pioneering blown film extruder manufacturers in Taiwan, KANG CHYAU. For more information and/or inquiry, please directly contact the manufacturer at the link given above. For any assistance, PRM will be more than happy to assist, please just leave a comment below. Then we will reply and contact you asap. Machinery in the Video: HDPE LDPE LLDPE (ABA) Two Layer Blown Film Machine from KANG CHYAU MODEL: KMTL-50S SUITABLE MATERIAL: HDPE / LDPE / LLDPE APPLICATIONS: Car Film, Food Packaging, Courier Bag, and so on. FILM THICKNESS: 0.010-0.15 mm FILM WIDTH RANGE: 1200 mm FILM OUTPUT: 90-140 kgs/hr

2024 CHINAPLAS Interview | King Plus

They are the manufacturer of blown film machines. In the past thirty-five years, Han King has relentlessly accumulated vast experience, from manufacturing mono-layer machines to two-layer, three-layer, and five-layer machines. We develop and produce our rotary die, embossing device, 360-degree oscillating haul-off, internal bubble cooling system, automatic air ring, and other blown film machine components.

Bio Resin Bag Making Line - JIT Series | JANDI’S

JANDI'S INDUSTRIAL CO., LTD. is committed to developing blown film machines combined with bag making, printing, and recycling machines. Until 2018, they obtained more than 30 patents of plastic machinery in China and Taiwan. With the concept of plastic reduction raising, JANDI'S proposes an idea about green innovation. The company develops JIT series integrated plastic bag making machines that are 100% suitable with biodegradable and compost materials such as PBAT and PLA. Moreover, JANDI'S added the automatic packaging part to JIT series.

Blown Film and Recycling Machines - POLYSTAR | CHINAPLAS 2021

PRM Media Channel once again happy to share the great honor of the cooperation with CPRJ, the official media group of CHINAPLAS. Through this cooperation, we aim to provide insights into the Plastics and Rubber industry by the sharing of experts. In this video, we have invited Mr. David Lo, Chief Marketing Officer, to share his knowledge and the overview of Blown Film Extrusion Machines and Plastics Recycling Machines markets. POLYSTAR Machinery is one of the most famous manufacturers especially in recycling machines in Asia with more than 30 years of experience. Besides recycling machinery, the company also well known around the world with its blown film machine lines. Most of the customers of POLYSTAR buy several sets of blown film machines as well as recycling machines together to set a complete line in their factories and contribute to the circular economy. In this video, Daniel from PRM will be carrying the interview with the Chief Marketing Officer Mr. David Lo. During the interview, Mr. Lo is explaining the advantages for the customers having both blown film machines and recycling machines from POLYSTAR. The following, interview covers several topics including: 1. Advantages of POLYSTAR recycling and blown film machines 2. POLYSTAR contribution to circular economy and examples 3. Simplifying machine design for ease of use 4. Vision and development in 2021

2024 CHINAPLAS Interview | ETERLONG

We are here with Melody from Eterlong Co., Ltd at the CHINAPLAS. ETERLONG is known for high-quality products, such as blown film machines, extrusion die and extruder filters, and their post-sale service. We gained information about how ETERLONG applies digitalization to their equipment.

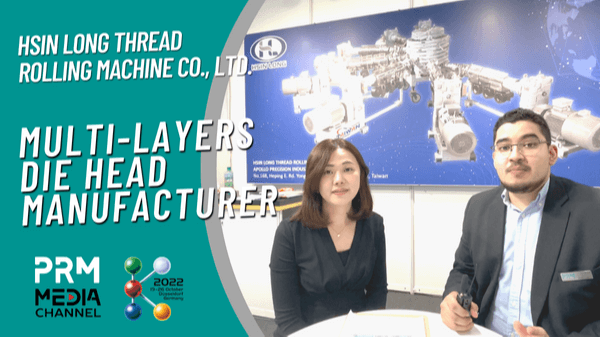

Multi-layers Die Head Manufacturer at K 2022 | HSIN LONG

Hsin Long Thread Rolling Machine Co., Ltd. is knowing for high-quality products, such as blown film machine, extrusion die and extruder filter, and their post-sale service. By interviewing Ms. Sandy Chen, Production Manager, we gained the information about how Hsin Long apply digitalization in their equipment.

Recycling Solutions for Packaging Industry | POLYSTAR Interview

At the recent TAIPEI PACK 2020, the famous packaging machinery exhibition of Taiwan, we have interviewed Ms. June Pei, from POLYSTAR. POLYSTAR is one of the most famous and leading recycling and blown film machines manufacturer from Taiwan, and has sold machinery in many countries around the globe. Ms. Pei shared her opinions and observations about the packaging industry, their recycling solutions related to the packaging industry, and also introduced the machinery they are showcasing at the exhibition. Moreover, she also mentioned the implementations to ease the effects of the pandemic on the business and the solutions they provide to their current and potential customers. Let's watch the interview video together and learn more. Thank you for your opinions and questions that you can leave as a comment. Remember to subscribe to our social media channels for the forthcoming interview videos and similar videos!~

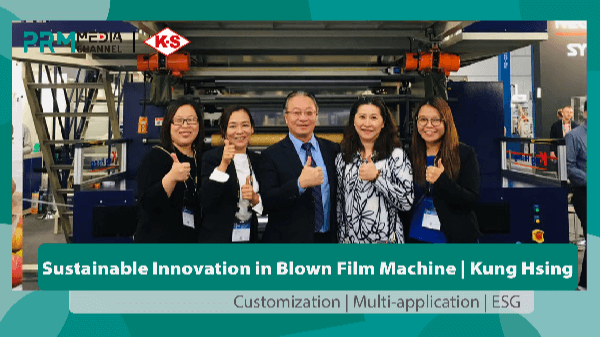

Sustainable Innovation of Blown Film Machine | KUNG HSING-

The latest innovation of Three Layer Blown Film Machine is featured with 3 in 1 Gap Winder that combines Surface Type, Contact Drive Type and Gap Winding. We are pleased to invite Kung Hsing Machinery to share the insight of the Blow Film Industry with us, which includes application, ESG and the effect of geopolitic to the economy.

Sustainable Innovation of Blown Film Machine | KUNG HSING

The latest innovation of Three Layer Blown Film Machine is featured with 3 in 1 Gap Winder that combines Surface Type, Contact Drive Type and Gap Winding. We are pleased to invite Kung Hsing Machinery to share the insight of the Blow Film Industry with us, which includes application, ESG and the effect of geopolitic to the economy. 【Product Features】 ● Five layers co-extrusion blown film line ● Φ300 mm Die : Production output 600 kg / hr ● Gain in weight gravimetric dosing unit ( Italy made) ● Profile measurement & auto thickness control (Auto Air Ring-Height Adjustable, High Efficiency Cooling and High Output Rate, Germany made) ● IBC computer control system (U.S.A Made) ● Horizontal oscillating take-up unit ● 3 in 1 Gap winder ( Surface type, Contact Drive Type and Gap Winding) 【Video Outline】 0:00 Welcome to K 2022 0:24 Introduction of Kung Hsing Machinery 0:53 Highlights of Kung Hsing at K 2022 1:54 Applications of KS Blown Film Machines 2:34 Upgrade of Three Layer Blown Film Machine 5:38 Strategy and Implementation to ESG 6:51 Customer Oriented Service 7:54 Advantages of Taiwanese Supply Chain 8:54 Occurrences affect Global Market 10:04 Development Trends of KS Blown Film Machine 11:07 More information on PRM B2